How to Choose the Right Perforated Metal for Soundproofing Applications

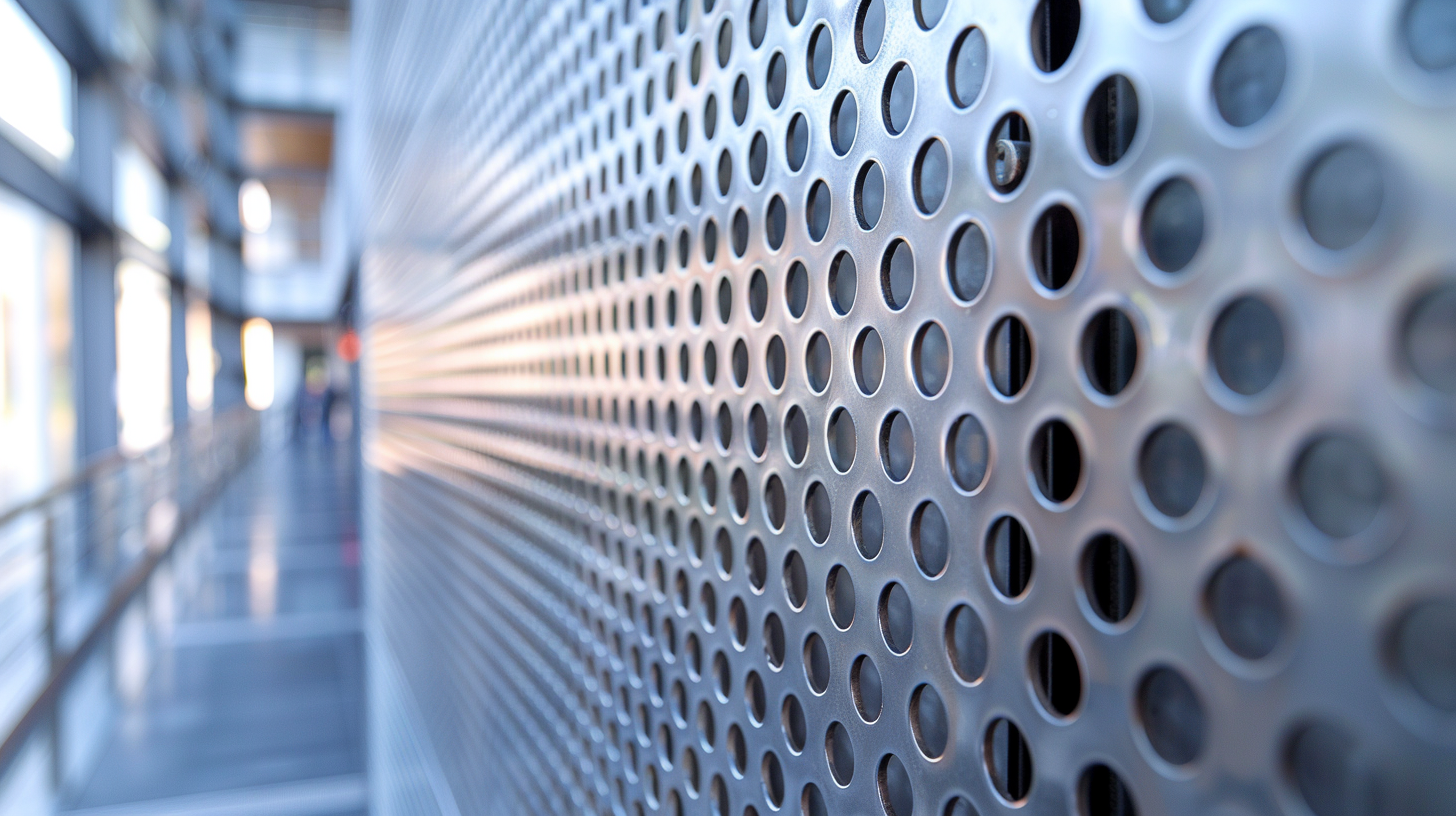

Soundproofing is a crucial consideration in many environments, from industrial facilities to office spaces and residential buildings. Perforated metal sheets are an effective solution for soundproofing due to their ability to absorb and diffuse sound waves. This article provides insights into choosing the right perforated metal for soundproofing applications.

Factors to Consider

1. Material Selection:

The choice of material for perforated metal is critical in soundproofing applications. Common materials include stainless steel, aluminum, and galvanized steel. Each material offers unique properties:

- Stainless Steel: Offers durability and corrosion resistance, ideal for harsh environments.

- Aluminum: Lightweight and easy to install, suitable for architectural applications.

- Galvanized Steel: Cost-effective and provides good corrosion resistance.

2. Hole Patterns:

The pattern and size of the holes in perforated metal sheets significantly impact their sound-absorbing properties. Different hole patterns, such as staggered, straight, or decorative, can be chosen based on the specific soundproofing needs and aesthetic preferences. Smaller hole sizes and higher open area percentages typically offer better sound absorption.

3. Thickness:

The thickness of the perforated metal sheet also plays a role in its soundproofing effectiveness. Thicker sheets can provide better sound insulation but may be heavier and more challenging to install. It’s essential to balance thickness with the installation requirements and the desired level of soundproofing.

4. Installation Method:

The method of installing perforated metal sheets can affect their soundproofing performance. Proper installation, including the use of sound-absorbing materials behind the perforated metal, can enhance its effectiveness. Techniques such as mounting on resilient channels or using acoustic insulation can improve soundproofing outcomes.

Real-World Applications

Perforated metal sheets are used in various soundproofing applications, including:

- Industrial Facilities: To reduce noise from machinery and equipment.

- Office Spaces: To create a quieter working environment by absorbing ambient noise.

- Residential Buildings: To enhance privacy and reduce noise from outside sources.

Expert Recommendations

When selecting perforated metal for soundproofing, consider consulting with an acoustic engineer or a soundproofing specialist. They can provide tailored recommendations based on the specific needs of the project and ensure the chosen solution delivers optimal results.

Case Study

A recent project involved the installation of aluminum perforated metal panels in an office building to address noise issues. The panels, featuring a staggered hole pattern and a high open area percentage, were installed with acoustic insulation backing. The result was a significant reduction in noise levels, creating a more conducive working environment.

Conclusion

Choosing the right perforated metal for soundproofing involves considering factors such as material, hole patterns, thickness, and installation methods. By understanding these elements and consulting with experts, you can select a solution that effectively reduces noise and enhances the acoustic quality of the space.

For more information on perforated metal sheets for soundproofing, visit our product page