How Perforated Metal Enhances Airflow in Industrial Settings

Introduction

Efficient airflow is critical in many industrial settings, from manufacturing plants to processing facilities. One material that has proven invaluable in optimizing airflow is perforated metal. Its design, with a variety of hole patterns and sizes, allows for enhanced ventilation, cooling, and air distribution, making it a staple in industrial environments.

The Role of Perforated Metal in Ventilation Systems

Perforated metal is widely used in ventilation systems due to its ability to allow controlled airflow while providing structural integrity. The holes in the metal allow air to pass through freely, which is essential in environments where maintaining consistent airflow is crucial for temperature control, air quality, or process efficiency. Additionally, perforated metal can help reduce noise levels, creating a more comfortable working environment.

Applications in Industrial Cooling

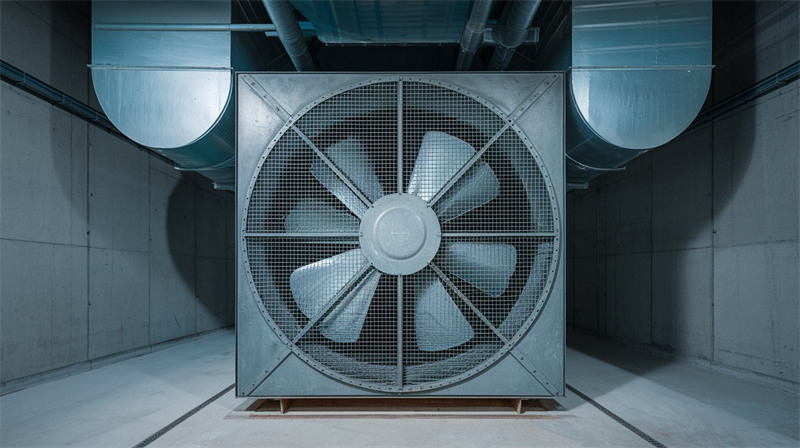

In industries that rely on machinery and equipment that generate a lot of heat, maintaining proper cooling systems is vital to avoid overheating and costly downtime. Perforated metal panels are often used in the design of cooling systems because they allow for the rapid dispersion of heat while protecting equipment from external debris. The customizable nature of perforated metal makes it adaptable for various cooling solutions, whether used in HVAC systems, cooling towers, or protective enclosures.

Improving Safety and Efficiency

One of the most significant advantages of perforated metal is its role in improving safety and operational efficiency. The metal panels can be designed to fit specific airflow requirements, ensuring that air circulates properly throughout the facility while preventing blockages or pressure build-up. Moreover, its ability to be tailored to various thicknesses and patterns means that perforated metal can provide the perfect balance between airflow and physical protection.

Case Study: Perforated Metal in Food Processing Plants

A food processing plant in the United States recently upgraded its ventilation system using perforated metal panels. The new design not only improved airflow but also enhanced hygiene by preventing airborne contaminants from entering critical processing areas. The result was a noticeable improvement in air quality, which contributed to higher production efficiency and compliance with stringent health regulations.

Conclusion

Perforated metal is a versatile material that offers numerous benefits in industrial airflow and ventilation systems. Its ability to promote efficient air distribution, reduce noise, and improve safety makes it an indispensable component in industrial design. Whether used for ventilation, cooling, or protective barriers, perforated metal enhances both performance and safety in demanding industrial environments.