Analysis of the cause of the failure of stainless steel filter valves

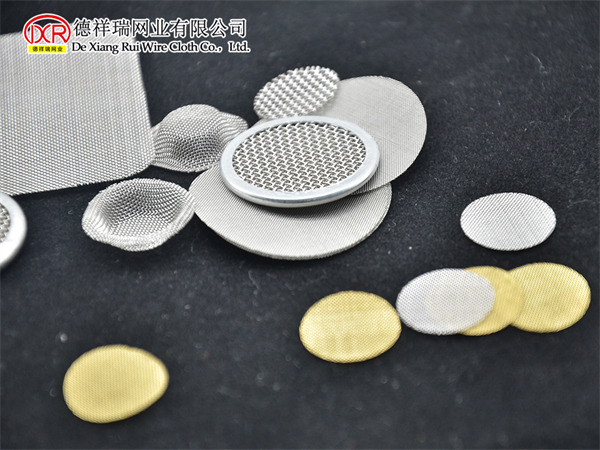

The cause of the breakdown failure after 18 months of the stainless steel filter valve worked for 18 months, and the fracture valve was detected and analyzed for the fracture valve, the gold phase tissue, and the chemical composition. Results show that the cracked position of the valve is a shell and the filter element reassess the site, that is, to withstand the largest part of the gas pressure, the source of the erosion and the crack source originated from the root of the inner thread, extended to the surface of the inside of the valve shell to the outside The material is ferrite+martensite bilateral tissue, and the volume score of the perchine tissue is 15%to 25%. Below the valve body’s broken mouth is flat, and cracks between the grains are all over, showing the characteristics of crispy fragments. There are large deviations in the CR and Ni content in the filter valve body structure, and the content of ferrite is greater than 10%, which reduces the plastic toughness of the material. This is the inherent factor in the failure of the material; The erosion is mixed with the second phase of the carbon -rich and chromium in the material recovery, and cracks in the area where the stress concentration is concentrated. Under the influence of the alternating stress, the crack is further expanded, and the material will eventually break.