Improvement of the spray packing structure of the power plant deaerator

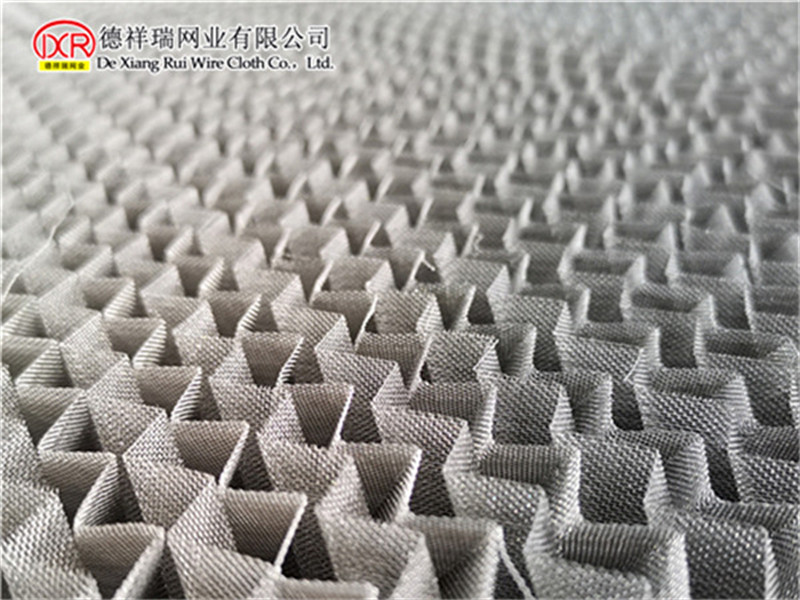

Although the original packing layer of the power plant deaerator uses eight layers of packing, it is difficult to achieve the ideal water film state because some of them have been broken, tilted, and shifted. The water sprayed after spray deaeration forms a water flow on the wall of the deaerator. Although it is redistributed on the water spray plate again through the water collecting cone, it is difficult to achieve the original design of evenly distributing the water in the spray layer on the packing due to its structure (more than 4,000 Φ8 holes are opened on the large disc with a diameter of 1300mm). Due to the poor state of the water film, the spraying on the packing layer is uneven, so the sprayed water and the upward secondary steam cannot fully carry out the heat and mass transfer process, especially the mass transfer process.

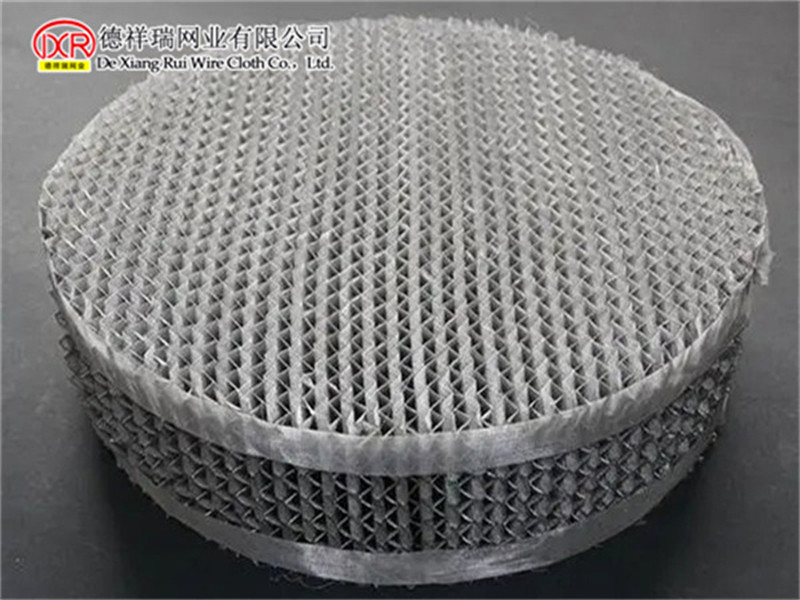

Only eight layers of packing cannot meet the requirements, which is one of the reasons why the deaerator has poor deoxygenation depth. Therefore, the following corresponding measures were taken:

a) Replace the packing layer that has fallen off, is short, tilted, or broken;

b) Add two more layers of packing in a limited space;

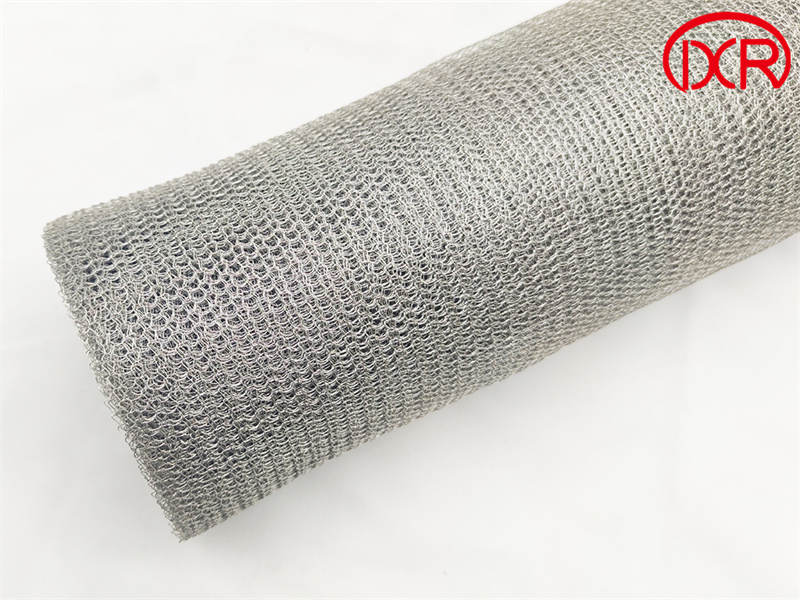

c) Fill the top of the water tray with stainless steel wire mesh to ensure the uniformity of the water droplets sprayed on the packing layer.